In the realm of monumental engineering feats, tunnel boring machines stand as colossal giants, undertaking the Herculean task of carving pathways through the earth’s crust. These behemoths, often referred to as TBMs, are the unsung heroes behind some of the world’s most intricate tunneling projects. This article takes you on a journey into the heart of these mechanical marvels, exploring their intricacies and shedding light on the extraordinary work they accomplish.

When it comes to tunneling on an unprecedented scale, the Tunnel Boring Machine reigns supreme. Towering over conventional equipment, these mechanical titans are purpose-built to tackle the most demanding subterranean challenges. From creating transportation tunnels to laying the groundwork for underground infrastructure, their capabilities are nothing short of awe-inspiring.

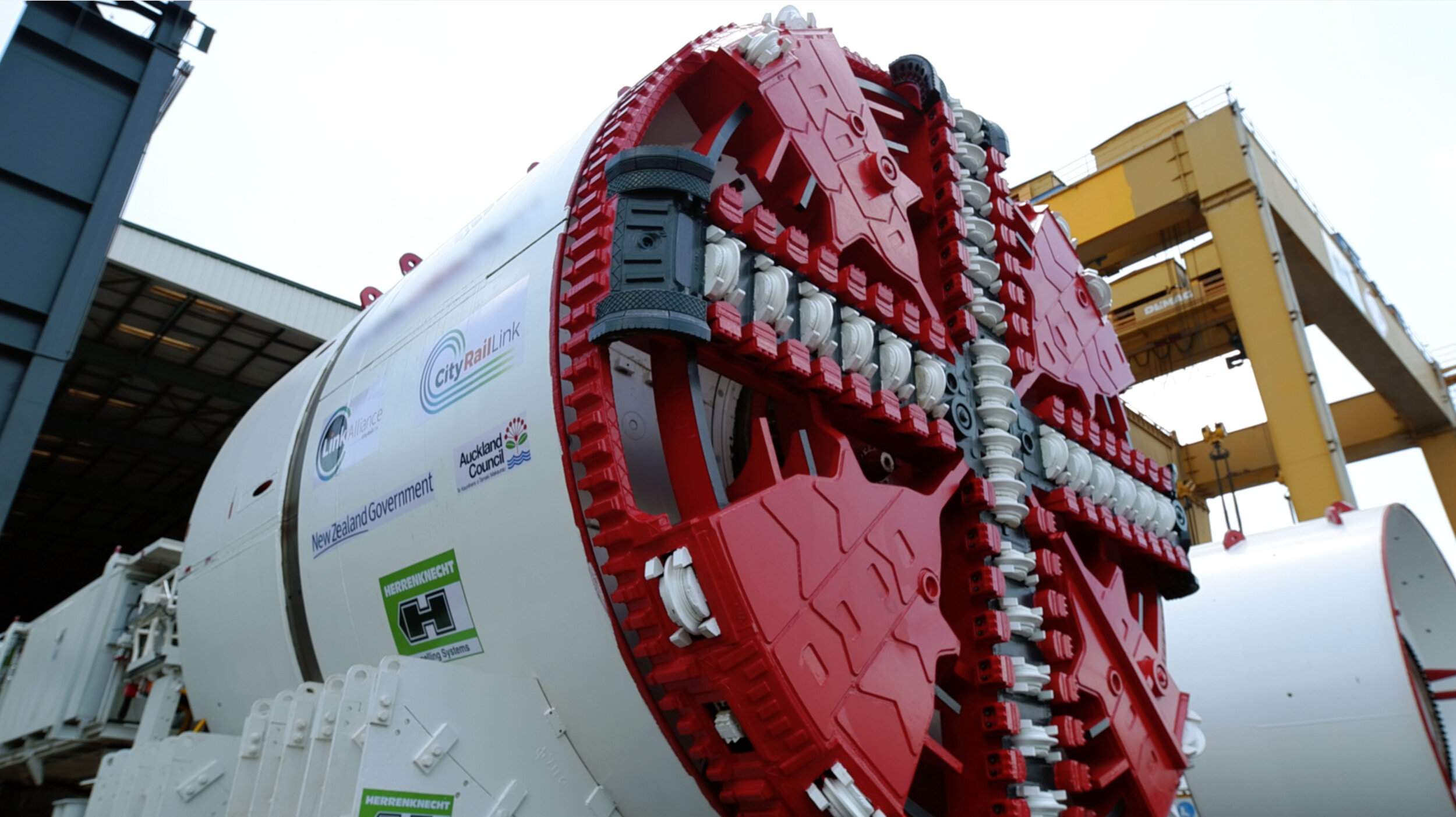

At the core of a Tunnel Boring Machine’s prowess lies its ability to navigate the extreme conditions of subterranean environments. Equipped with cutting-edge technology and an array of specialized tools, these machines bore through solid rock and compacted soil with relentless precision. Their massive rotating cutterheads exert immense force, pulverizing obstacles that stand in their path. As they advance, they simultaneously install tunnel linings, ensuring stability and safety throughout the excavation process.

The process begins with the TBM’s entry into the earth’s crust. Guided by a team of skilled operators and sophisticated control systems, the machine’s cutterhead makes initial contact with the rock or soil. Slowly but steadily, it begins to exert pressure, gradually forging a path forward.

As the cutterhead rotates, its formidable teeth make contact with the geological formations. Through a combination of rotary motion and thrust, the TBM chips away at the material, creating a tunnel of precise dimensions. Simultaneously, the spoil is transported back along a conveyor belt, clearing the way for further excavation.

To ensure the stability of the newly created tunnel, TBMs incorporate a simultaneous lining installation process. Sections of pre-fabricated tunnel lining, often composed of reinforced concrete segments, are carefully positioned in place. This not only fortifies the tunnel’s structural integrity but also protects against potential instabilities.

Witnessing a Tunnel Boring Machine in action is akin to observing a carefully choreographed dance of technology and engineering. Each movement is deliberate, each component meticulously designed to withstand the unforgiving pressures of the subterranean world.

In the grand tapestry of modern engineering, Tunnel Boring Machines emerge as unsung heroes, enabling the creation of intricate subterranean networks that shape our cities and connect our worlds. Their ability to conquer the depths with precision and power is a testament to human ingenuity and the relentless pursuit of progress. As they burrow through the earth, they remind us that beneath our feet lies a world of marvels waiting to be unearthed.

Close