The Comprehensive Guide to Manufacturing Large Piston Rings

Piston rings are crucial components in an internal combustion engine, ensuring the engine runs smoothly and efficiently. This article delves into the meticulous manufacturing process of large piston rings, highlighting the intricate steps involved in their creation.

Material Selection and Preparation

The manufacturing journey begins with the selection of high-quality materials. Cast iron is predominantly used due to its excellent wear resistance and compatibility with engine lubricants. Once the material is chosen, it undergoes melting and casting to form cylindrical billets. These billets serve as the raw material for the piston rings.

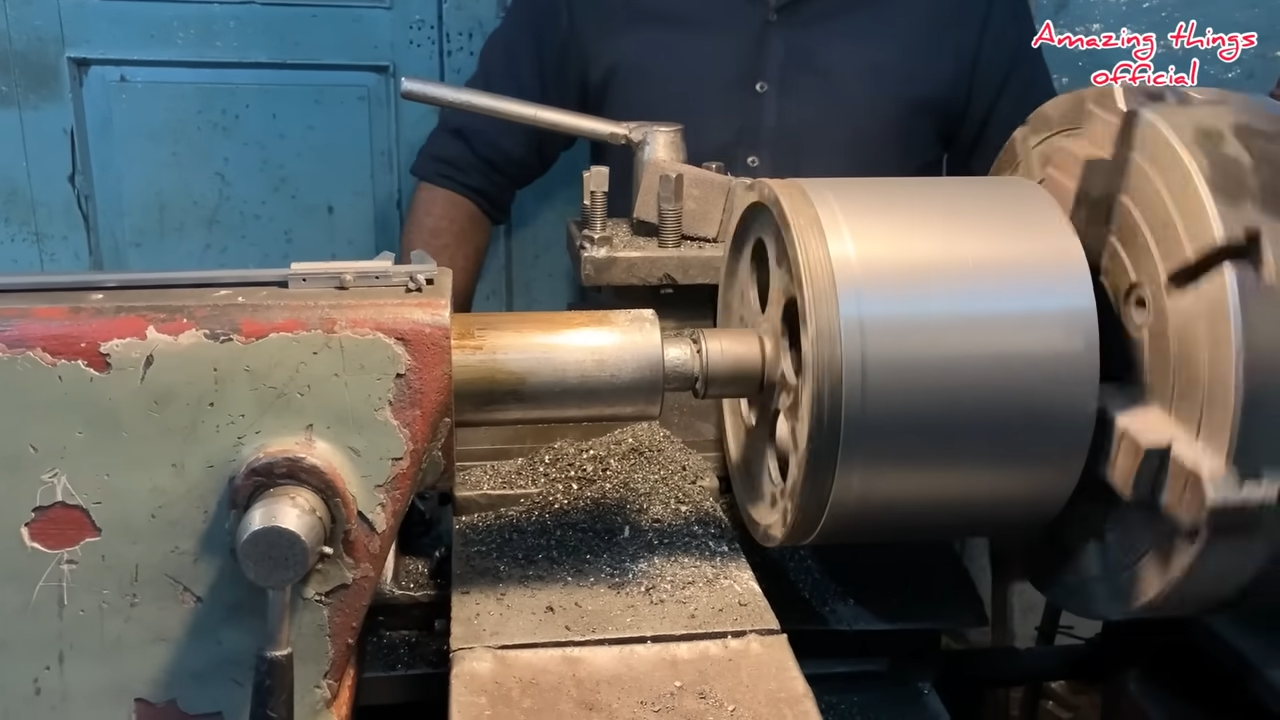

Cutting and Machining

The next phase involves cutting the billets into smaller, manageable pieces. Precision is paramount in this step to ensure each piece meets the required dimensions. These smaller pieces are then machined into the initial ring shape. Advanced CNC machines play a vital role in achieving the desired accuracy and consistency during this process.

Heat Treatment

Heat treatment is a crucial step in the manufacturing process, as it enhances the mechanical properties of the piston rings. The machined rings are heated to high temperatures and then rapidly cooled. This treatment process, known as quenching, increases the hardness and durability of the rings, making them capable of withstanding the harsh conditions inside an engine.

Finishing and Grinding

After heat treatment, the piston rings undergo a series of finishing operations. Grinding is performed to achieve the final dimensions and surface finish. This step ensures the rings fit perfectly into the engine’s cylinder and create an effective seal. Precision is key, as any deviation can lead to engine performance issues.

Surface Coating

To further enhance the performance and longevity of piston rings, they are often coated with special materials. These coatings reduce friction and wear, improving the overall efficiency of the engine. Common coatings include chromium, molybdenum, and various proprietary blends designed to withstand high temperatures and pressures.

Quality Control

Quality control is an integral part of the manufacturing process. Each piston ring undergoes rigorous inspection to ensure it meets stringent industry standards. Measurements are taken to verify dimensions, and various tests are conducted to assess hardness, surface finish, and overall performance. Only rings that pass these tests are deemed suitable for use in engines.

Packaging and Distribution

The final step in the process is packaging and distribution. The piston rings are carefully packaged to prevent damage during transportation. They are then shipped to engine manufacturers and aftermarket suppliers around the world, ready to be installed in a wide range of engines.

Conclusion

The production of large piston rings is a complex and precise process that involves multiple steps, from material selection to final inspection. Each stage is critical in ensuring the rings perform optimally in an engine. By adhering to stringent quality control measures and utilizing advanced manufacturing techniques, manufacturers can produce piston rings that contribute to the efficiency and reliability of internal combustion engines.