Dive Into the World of Skilled Electrical Engineers Creating the Largest Electric Motor (Video)

The world’s largest electric motor is an impressive feat of engineering, requiring the expertise of some of the most skilled electrical engineers and the best teamwork to produce. The process of designing and building such a motor is complex and requires careful planning, precision, and attention to detail.

The design process began with a thorough analysis of the intended use of the motor. This included determining the required power output, efficiency, and other specifications. The design team then used advanced software to create a detailed model of the motor, taking into account various factors such as size, weight, and materials.

Once the design was complete, the manufacturing process began. The motor was constructed using high-strength materials, such as steel and copper, to ensure its durability and performance. The manufacturing team worked closely with the design team to ensure that the motor was built according to specifications and met all necessary standards.

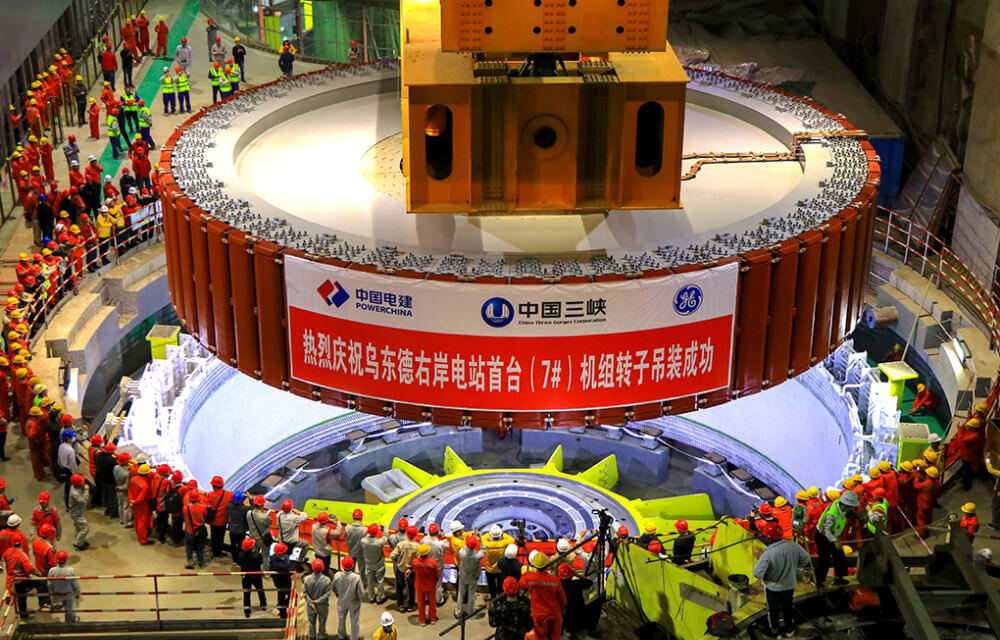

The assembly of the motor required precise coordination and teamwork. Skilled electrical engineers and technicians worked together to ensure that all components were assembled correctly, with no mistakes or errors. They used specialized tools and equipment to ensure that the motor was aligned and balanced correctly, and that all wiring and connections were secure.

Once the motor was fully assembled, it underwent rigorous testing to ensure that it met all performance specifications. This included testing for efficiency, power output, and durability. Any issues or problems were addressed and corrected to ensure that the motor was of the highest quality.

In conclusion, the production of the world’s largest electric motor required the expertise of the most skilled electrical engineers and the best teamwork. From the design process to manufacturing, assembly, and testing, every aspect of the process was carefully considered and executed with precision. The result is a remarkable achievement of engineering and a testament to human ingenuity and teamwork.

Video: